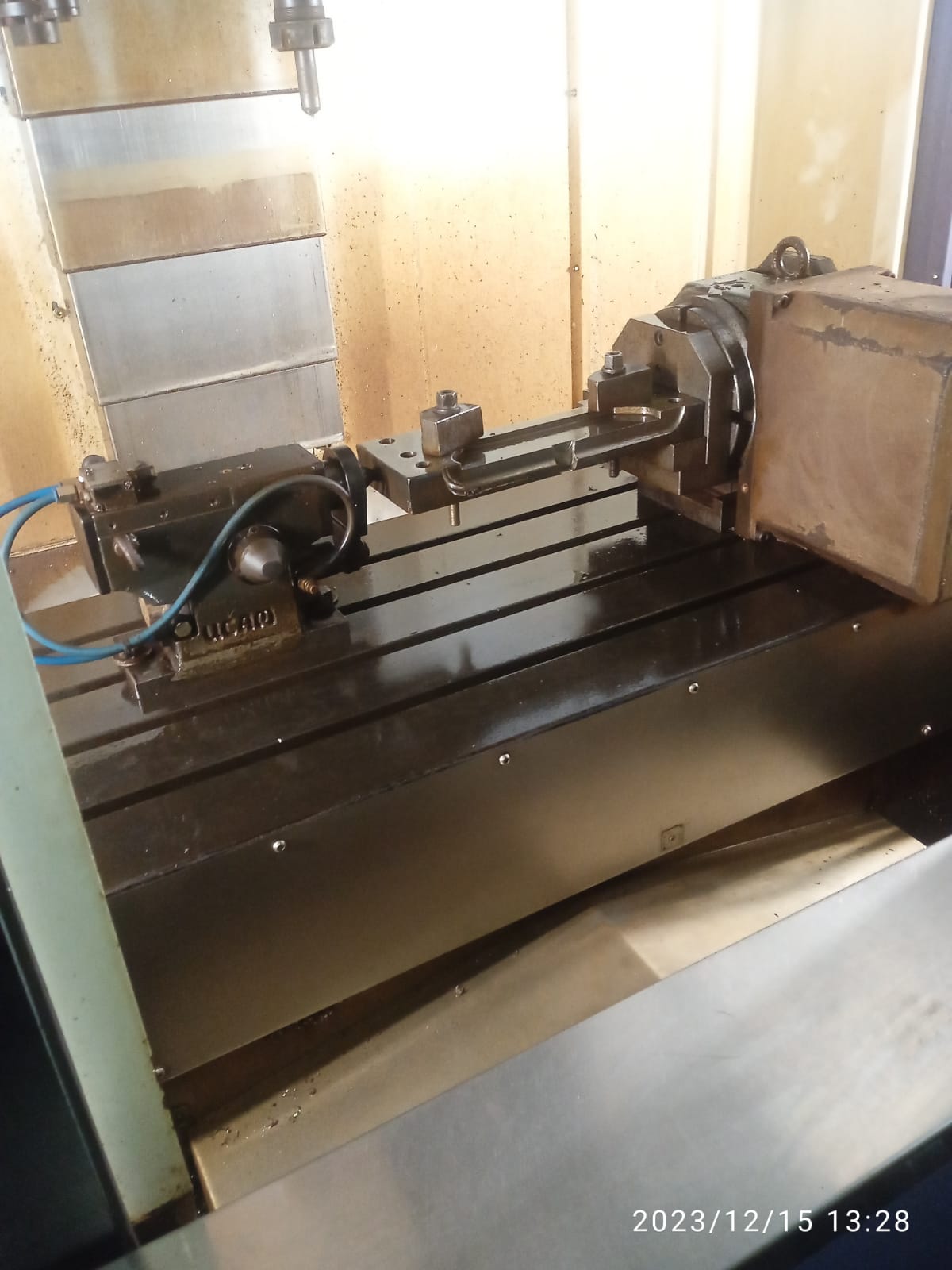

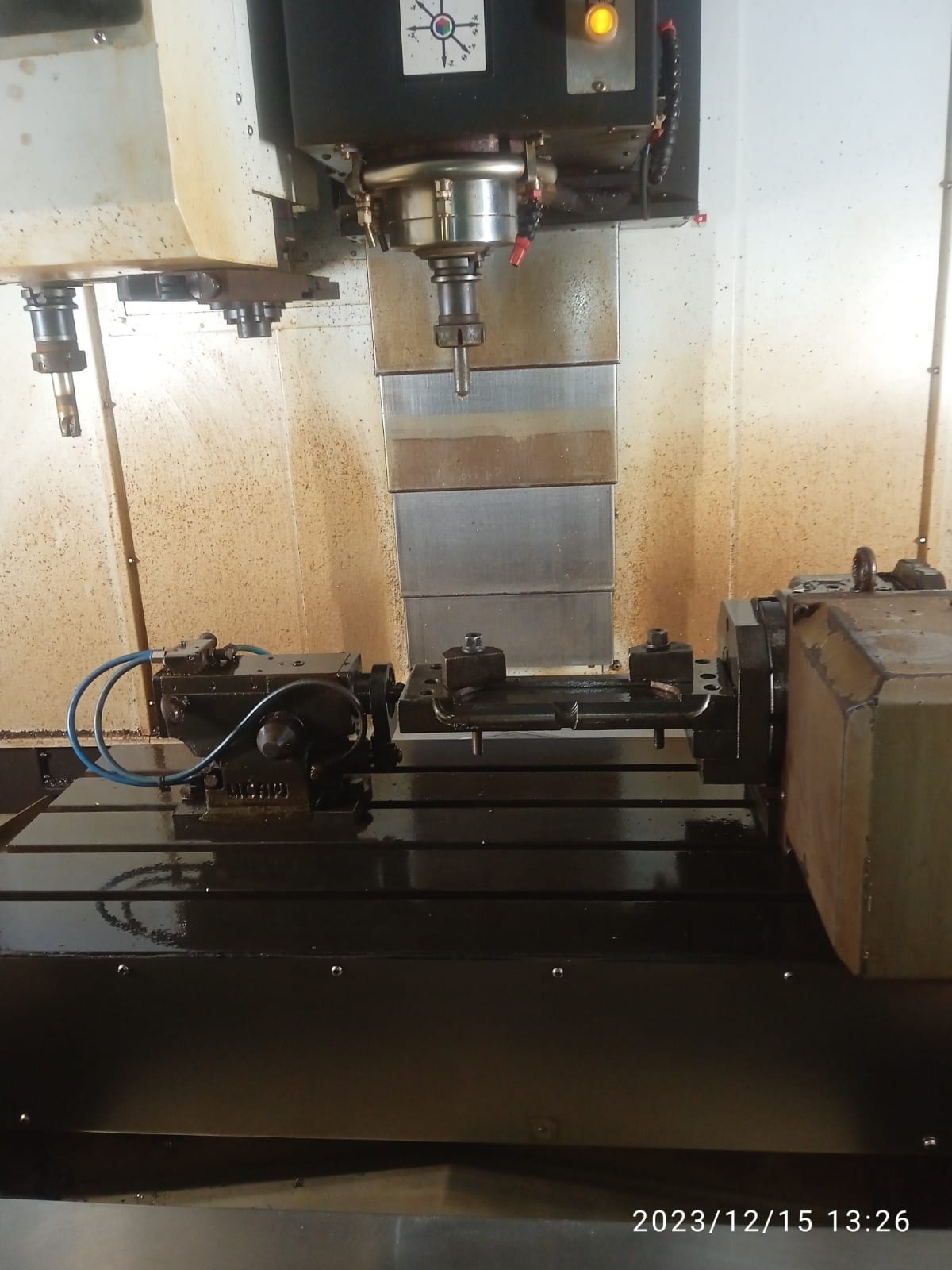

VIBRANT 800 Vertical Machining Center

₹24.00 Lakh

This is a Vertical Machining Center

| Description | Unit | VIBRANT 800 |

| CAPACITY | ||

| X Axis Travel | mm | 820 |

| Y Axis Travel | mm | 510 |

| Z Axis Travel | mm | 510 |

| Rapid Feed Rates X/Y/Z Axis | m/min | 24/24/24 |

| Distance from Table to Spindle Face | mm | 100-610 |

| TABLE | ||

| Table Size (Clamping Area) | mm | 500 x 1050 |

| No./Width/CD of T-slots | mm | 4/14/100 |

| Max. safe load on Table | Kg | 500 |

| MAIN SPINDLE | ||

| Taper | — | BT-40 |

| Speed | rpm | 80-8000 |

| Cutting Feed Rate | mm/min | 1-10000 |

| Rated Power (Fanuc) | kW | 7.5/11 |

| AUTO TOOL CHANGER | ||

| Type | — | Twin Arm |

| No. of Tools | — | 24 |

| Tool Selection | — | Random |

| Max. Tool Dia. (Pocket full/empty) | mm | 80/125 |

| Tool Length | mm | 250 |

| Tool Weight | Kg | 7 |

| ACCURACY (AS PER JIS) | ||

| Positioning Accuracy | mm | 0.01 |

| Repeatability | mm | 0.007 |

| INSTALLATION DATA | ||

| Pneumatic Supply | bar | 6 |

| Machine Weight (Approx) | Kg | 4900 |

| Total Connected Load | KVA | 20 |

| Power Supply | — | AC 440 V, 50HZ, 3 Ph. |

| Machine Dimensions (WxDxH) (Approx) | mm | 2604x2782x2995 |

| CONTROL SYSTEM | ||

| Fanuc | — | Oi MF PLUS |

| Siemens | — | 828D |

| Mitsubishi | — | M 80 |

An Automatic Vertical Machining Center (VMC) is a type of machining center that combines automated features with vertical spindle orientation. It is designed to perform a range of machining operations with minimal manual intervention, allowing for increased productivity and efficiency in manufacturing processes.

Here are some key features and capabilities of an Automatic Vertical Machining Center:

- Automated Tool Changer: An Automatic VMC is equipped with an automatic tool changer (ATC) that allows for the automatic exchange of cutting tools during the machining process. The ATC typically holds a variety of tools in a tool magazine, and the machine’s control system manages tool changes based on the programmed instructions.

- CNC Control System: Automatic VMCs are controlled by computer numerical control (CNC) systems. The CNC system interprets machining programs, which are typically generated using computer-aided manufacturing (CAM) software, and controls the machine’s movements, spindle speed, tool changes, and other parameters. CNC control enables precise and automated execution of complex machining operations.

- Axis Movement: Automatic VMCs feature multiple axes of movement, typically including X, Y, and Z axes. These axes allow for precise positioning and movement of the workpiece and cutting tools. The machine’s control system coordinates the movements of the axes to execute machining operations accurately.

- Vertical Spindle Orientation: VMCs have a vertically oriented spindle, positioned perpendicular to the worktable. The spindle rotates at high speeds to drive the cutting tools during machining operations. The vertical spindle orientation offers advantages such as good chip evacuation and accessibility to workpieces from different angles.

- Worktable and Fixturing: Automatic VMCs have a worktable that holds the workpiece securely during machining. The worktable can move along the various axes to position the workpiece accurately. Fixturing options such as vises, clamps, and fixtures are used to hold the workpiece in place during machining operations.

- Precision and Accuracy: Automatic VMCs are known for their ability to achieve high levels of precision and accuracy. The combination of rigid machine construction, precise control systems, and accurate positioning allows for the production of parts with tight tolerances and excellent surface finishes.

- Applications: Automatic VMCs find application in various industries, including automotive, aerospace, medical, and general manufacturing. They are capable of performing a range of operations such as milling, drilling, tapping, contouring, and pocketing on different materials, including metals, plastics, and composites

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.

This is a Vertical Machining Center

| Description | Unit | VIBRANT 800 |

| CAPACITY | ||

| X Axis Travel | mm | 820 |

| Y Axis Travel | mm | 510 |

| Z Axis Travel | mm | 510 |

| Rapid Feed Rates X/Y/Z Axis | m/min | 24/24/24 |

| Distance from Table to Spindle Face | mm | 100-610 |

| TABLE | ||

| Table Size (Clamping Area) | mm | 500 x 1050 |

| No./Width/CD of T-slots | mm | 4/14/100 |

| Max. safe load on Table | Kg | 500 |

| MAIN SPINDLE | ||

| Taper | — | BT-40 |

| Speed | rpm | 80-8000 |

| Cutting Feed Rate | mm/min | 1-10000 |

| Rated Power (Fanuc) | kW | 7.5/11 |

| AUTO TOOL CHANGER | ||

| Type | — | Twin Arm |

| No. of Tools | — | 24 |

| Tool Selection | — | Random |

| Max. Tool Dia. (Pocket full/empty) | mm | 80/125 |

| Tool Length | mm | 250 |

| Tool Weight | Kg | 7 |

| ACCURACY (AS PER JIS) | ||

| Positioning Accuracy | mm | 0.01 |

| Repeatability | mm | 0.007 |

| INSTALLATION DATA | ||

| Pneumatic Supply | bar | 6 |

| Machine Weight (Approx) | Kg | 4900 |

| Total Connected Load | KVA | 20 |

| Power Supply | — | AC 440 V, 50HZ, 3 Ph. |

| Machine Dimensions (WxDxH) (Approx) | mm | 2604x2782x2995 |

| CONTROL SYSTEM | ||

| Fanuc | — | Oi MF PLUS |

| Siemens | — | 828D |

| Mitsubishi | — | M 80 |

An Automatic Vertical Machining Center (VMC) is a type of machining center that combines automated features with vertical spindle orientation. It is designed to perform a range of machining operations with minimal manual intervention, allowing for increased productivity and efficiency in manufacturing processes.

Here are some key features and capabilities of an Automatic Vertical Machining Center:

- Automated Tool Changer: An Automatic VMC is equipped with an automatic tool changer (ATC) that allows for the automatic exchange of cutting tools during the machining process. The ATC typically holds a variety of tools in a tool magazine, and the machine’s control system manages tool changes based on the programmed instructions.

- CNC Control System: Automatic VMCs are controlled by computer numerical control (CNC) systems. The CNC system interprets machining programs, which are typically generated using computer-aided manufacturing (CAM) software, and controls the machine’s movements, spindle speed, tool changes, and other parameters. CNC control enables precise and automated execution of complex machining operations.

- Axis Movement: Automatic VMCs feature multiple axes of movement, typically including X, Y, and Z axes. These axes allow for precise positioning and movement of the workpiece and cutting tools. The machine’s control system coordinates the movements of the axes to execute machining operations accurately.

- Vertical Spindle Orientation: VMCs have a vertically oriented spindle, positioned perpendicular to the worktable. The spindle rotates at high speeds to drive the cutting tools during machining operations. The vertical spindle orientation offers advantages such as good chip evacuation and accessibility to workpieces from different angles.

- Worktable and Fixturing: Automatic VMCs have a worktable that holds the workpiece securely during machining. The worktable can move along the various axes to position the workpiece accurately. Fixturing options such as vises, clamps, and fixtures are used to hold the workpiece in place during machining operations.

- Precision and Accuracy: Automatic VMCs are known for their ability to achieve high levels of precision and accuracy. The combination of rigid machine construction, precise control systems, and accurate positioning allows for the production of parts with tight tolerances and excellent surface finishes.

- Applications: Automatic VMCs find application in various industries, including automotive, aerospace, medical, and general manufacturing. They are capable of performing a range of operations such as milling, drilling, tapping, contouring, and pocketing on different materials, including metals, plastics, and composites

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.