CNC Turning Centers

₹13.00 Lakh

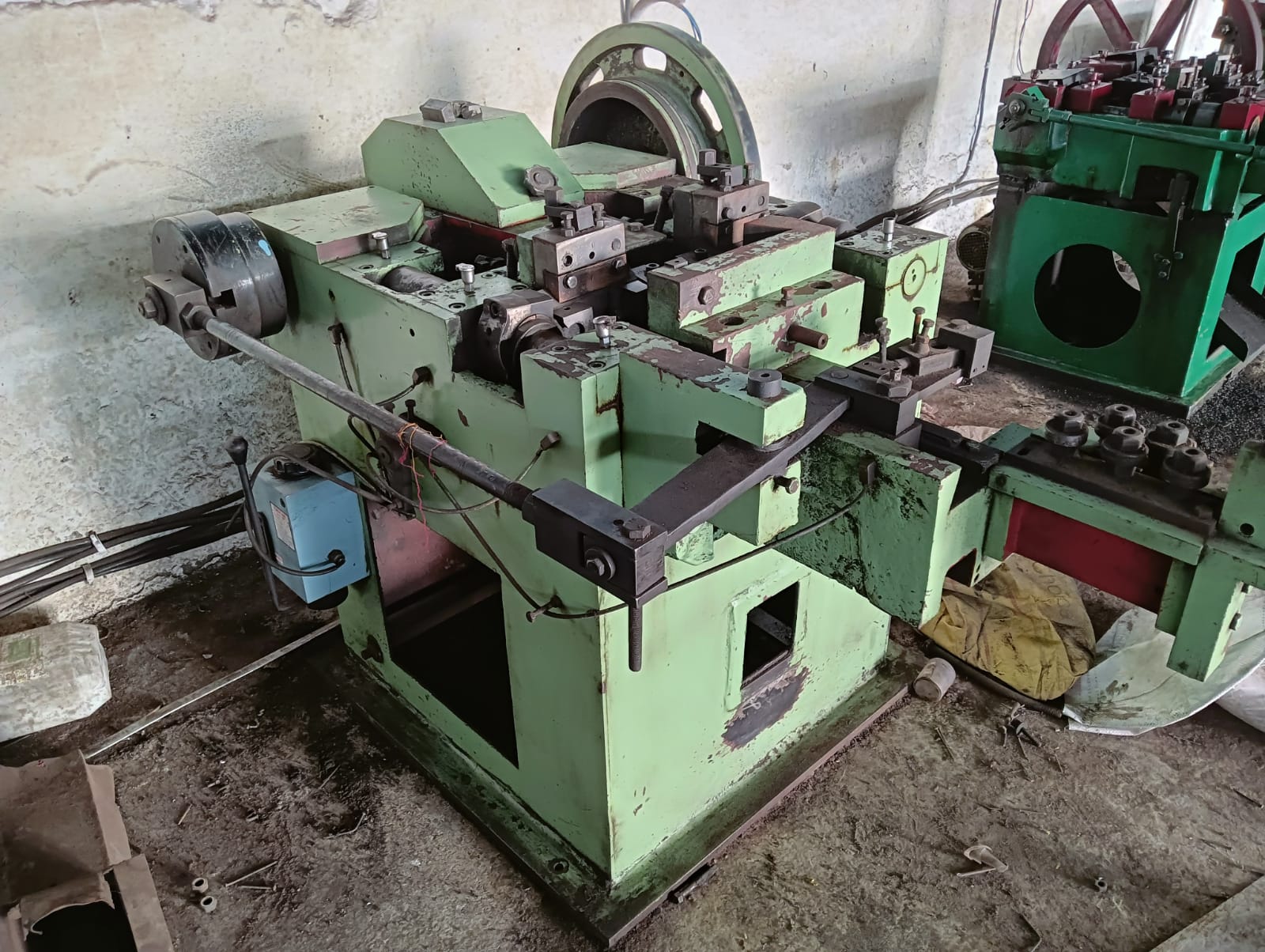

This is a CNC Turning Center

Product Specification

| Machining Axis | 4-Axis |

| Machine Type | Horizontal Turning Centre |

| Chuck Diameter | 300 mm |

| Country of Origin | Made in India |

| Voltage | 380 V |

| Frequency | 50 Hz |

CNC turning centers, also known as CNC lathes or CNC turning machines, are a type of computer-controlled machine tool used in the manufacturing industry for precision machining of cylindrical workpieces. These machines are equipped with a computer numerical control (CNC) system that automates and controls the machining process, allowing for high-precision and efficient production of complex parts. Here are some key features and functionalities of CNC turning centers:

- Turning Operations: The primary operation of CNC turning centers is turning, which involves rotating the workpiece while a cutting tool removes material to create the desired shape. Turning is commonly used to produce cylindrical components, such as shafts, pins, flanges, and various other symmetrical parts.

- Computer Numerical Control (CNC): The CNC system consists of a computer and software that interpret part programs, usually written in G-codes and M-codes. These codes control the movements of the cutting tool, the speed and direction of the spindle, and other machine functions.

- Multi-Axis Capability: CNC turning centers can have multiple axes of movement, typically X, Z, and C axes. The X-axis controls the horizontal movement of the cutting tool, the Z-axis controls the longitudinal movement of the tool along the workpiece, and the C-axis allows for rotation of the workpiece.

- Automatic Tool Change: Many CNC turning centers are equipped with an automatic tool changer (ATC) that can hold multiple cutting tools. The machine can automatically change tools during the machining process, enabling the production of complex parts without manual intervention.

- Bar Feeder and Chip Conveyor: Some CNC turning centers have a bar feeder that automatically supplies long bar stock into the machine, allowing for continuous production of parts without the need for manual reloading. Additionally, a chip conveyor removes the chips generated during machining, keeping the work area clean and ensuring smooth operation.

- Live Tooling Capability: Advanced CNC turning centers may feature live tooling, which means the machine can perform secondary operations, such as milling, drilling, and tapping, using powered rotating toolholders. This capability adds versatility and reduces the need for additional machining setups.

- Precision and Repeatability: CNC turning centers offer high precision and repeatability, allowing for the production of parts with tight tolerances. The accuracy and consistency of these machines make them suitable for applications requiring high-quality components.

- Versatility and Efficiency: CNC turning centers are used in a wide range of industries, including automotive, aerospace, medical, and general manufacturing. Their ability to produce complex parts with speed and accuracy makes them a valuable asset for various production needs.

CNC turning centers come in different sizes and configurations, ranging from small benchtop machines to large industrial models. The choice of machine depends on the specific requirements of the parts to be produced and the production volume. These machines continue to advance with improved automation, control systems, and cutting technologies, contributing to enhanced productivity and manufacturing capabilities.

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.

This is a CNC Turning Center

Product Specification

| Machining Axis | 4-Axis |

| Machine Type | Horizontal Turning Centre |

| Chuck Diameter | 300 mm |

| Country of Origin | Made in India |

| Voltage | 380 V |

| Frequency | 50 Hz |

CNC turning centers, also known as CNC lathes or CNC turning machines, are a type of computer-controlled machine tool used in the manufacturing industry for precision machining of cylindrical workpieces. These machines are equipped with a computer numerical control (CNC) system that automates and controls the machining process, allowing for high-precision and efficient production of complex parts. Here are some key features and functionalities of CNC turning centers:

- Turning Operations: The primary operation of CNC turning centers is turning, which involves rotating the workpiece while a cutting tool removes material to create the desired shape. Turning is commonly used to produce cylindrical components, such as shafts, pins, flanges, and various other symmetrical parts.

- Computer Numerical Control (CNC): The CNC system consists of a computer and software that interpret part programs, usually written in G-codes and M-codes. These codes control the movements of the cutting tool, the speed and direction of the spindle, and other machine functions.

- Multi-Axis Capability: CNC turning centers can have multiple axes of movement, typically X, Z, and C axes. The X-axis controls the horizontal movement of the cutting tool, the Z-axis controls the longitudinal movement of the tool along the workpiece, and the C-axis allows for rotation of the workpiece.

- Automatic Tool Change: Many CNC turning centers are equipped with an automatic tool changer (ATC) that can hold multiple cutting tools. The machine can automatically change tools during the machining process, enabling the production of complex parts without manual intervention.

- Bar Feeder and Chip Conveyor: Some CNC turning centers have a bar feeder that automatically supplies long bar stock into the machine, allowing for continuous production of parts without the need for manual reloading. Additionally, a chip conveyor removes the chips generated during machining, keeping the work area clean and ensuring smooth operation.

- Live Tooling Capability: Advanced CNC turning centers may feature live tooling, which means the machine can perform secondary operations, such as milling, drilling, and tapping, using powered rotating toolholders. This capability adds versatility and reduces the need for additional machining setups.

- Precision and Repeatability: CNC turning centers offer high precision and repeatability, allowing for the production of parts with tight tolerances. The accuracy and consistency of these machines make them suitable for applications requiring high-quality components.

- Versatility and Efficiency: CNC turning centers are used in a wide range of industries, including automotive, aerospace, medical, and general manufacturing. Their ability to produce complex parts with speed and accuracy makes them a valuable asset for various production needs.

CNC turning centers come in different sizes and configurations, ranging from small benchtop machines to large industrial models. The choice of machine depends on the specific requirements of the parts to be produced and the production volume. These machines continue to advance with improved automation, control systems, and cutting technologies, contributing to enhanced productivity and manufacturing capabilities.

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.