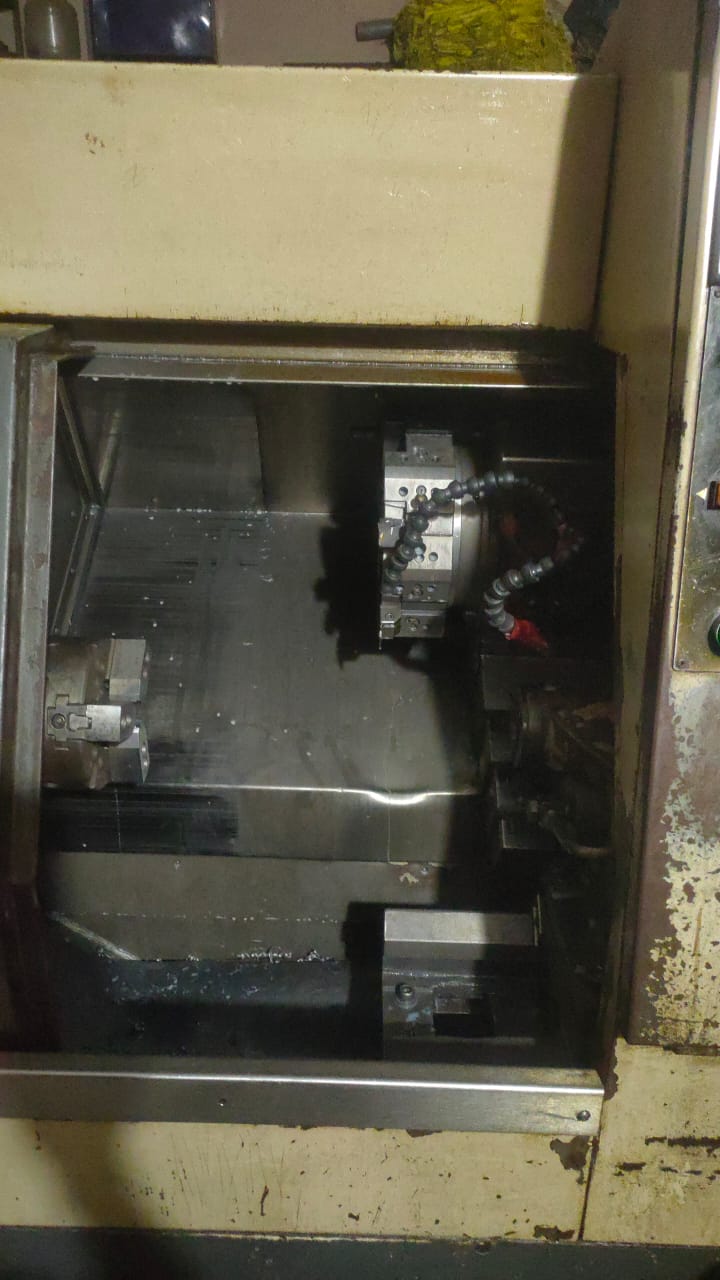

Galaxy 440V Midas 10 CNC Turning Machine

₹82.00 Lakh

This is a Galaxy 440V Midas 10 CNC Turning Machine

Product Specification

| Brand | Galaxy |

| Material | Mild Steel |

| Voltage | 440V |

| Automation Grade | Automatic |

| Frequency | 50 Hz |

| Max Speed | 5m/min |

| Max Torque | 4-6Nm |

| Weight | 1900KG |

CNC turning machines, also known as CNC lathes, are versatile machine tools used for various turning operations in the manufacturing industry. They are designed to accurately and efficiently shape cylindrical workpieces by rotating them against cutting tools. While specific features can vary across models, here are some common features of CNC turning machines:

- CNC Technology: The machine incorporates CNC (Computer Numerical Control) technology, enabling precise control and automation of machining operations. The CNC system controls the movement of the cutting tool, the workpiece, and other machine functions, ensuring accurate and repeatable machining according to programmed instructions.

- Turning Operations: CNC turning machines are primarily used for turning operations, including external and internal turning, facing, taper turning, threading, and grooving. They can produce a wide range of cylindrical shapes, such as straight, tapered, stepped, or contoured profiles.

- Spindle and Chuck: The machine is equipped with a spindle that rotates the workpiece and a chuck to securely hold it in place during machining. The spindle speed can often be adjusted to accommodate different cutting requirements, while the chuck provides gripping and stability for accurate machining.

- Tooling Options: CNC turning machines feature a tool turret or tooling system that holds multiple cutting tools. This allows for quick tool changes during machining operations, enhancing efficiency. Common tooling options include turning tools, boring bars, threading tools, drill bits, and grooving tools.

- Automatic Tool Control and Programming: CNC turning machines support automatic tool control, enabling fast and accurate tool changes and positioning. They also offer programming capabilities, where operators can input machining parameters, tool paths, and other instructions using the machine’s interface. This programming capability allows for efficient and repeatable machining operations.

- User-Friendly Interface and Controls: The machine typically features a user-friendly interface and controls that allow operators to input machining parameters, monitor the machining process, and make adjustments as needed. The interface provides real-time feedback, diagnostic information, and visualization of the machining operations, enhancing control and productivity.

- Workpiece Clamping and Fixturing: CNC turning machines offer various options for securely clamping and fixturing workpieces. This ensures stability during machining and reduces the risk of workpiece movement or vibrations, leading to precise and accurate results.

- Precision and Accuracy: CNC turning machines are known for their high precision and accuracy. They can achieve tight tolerances and produce smooth surface finishes, meeting the requirements of industries such as automotive, aerospace, medical, and more.

While the specific features of the “Galaxy 440V Midas 10 CNC Turning Machine” may differ, these general features represent the typical capabilities and functionalities of CNC turning machines

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.

This is a Galaxy 440V Midas 10 CNC Turning Machine

Product Specification

| Brand | Galaxy |

| Material | Mild Steel |

| Voltage | 440V |

| Automation Grade | Automatic |

| Frequency | 50 Hz |

| Max Speed | 5m/min |

| Max Torque | 4-6Nm |

| Weight | 1900KG |

CNC turning machines, also known as CNC lathes, are versatile machine tools used for various turning operations in the manufacturing industry. They are designed to accurately and efficiently shape cylindrical workpieces by rotating them against cutting tools. While specific features can vary across models, here are some common features of CNC turning machines:

- CNC Technology: The machine incorporates CNC (Computer Numerical Control) technology, enabling precise control and automation of machining operations. The CNC system controls the movement of the cutting tool, the workpiece, and other machine functions, ensuring accurate and repeatable machining according to programmed instructions.

- Turning Operations: CNC turning machines are primarily used for turning operations, including external and internal turning, facing, taper turning, threading, and grooving. They can produce a wide range of cylindrical shapes, such as straight, tapered, stepped, or contoured profiles.

- Spindle and Chuck: The machine is equipped with a spindle that rotates the workpiece and a chuck to securely hold it in place during machining. The spindle speed can often be adjusted to accommodate different cutting requirements, while the chuck provides gripping and stability for accurate machining.

- Tooling Options: CNC turning machines feature a tool turret or tooling system that holds multiple cutting tools. This allows for quick tool changes during machining operations, enhancing efficiency. Common tooling options include turning tools, boring bars, threading tools, drill bits, and grooving tools.

- Automatic Tool Control and Programming: CNC turning machines support automatic tool control, enabling fast and accurate tool changes and positioning. They also offer programming capabilities, where operators can input machining parameters, tool paths, and other instructions using the machine’s interface. This programming capability allows for efficient and repeatable machining operations.

- User-Friendly Interface and Controls: The machine typically features a user-friendly interface and controls that allow operators to input machining parameters, monitor the machining process, and make adjustments as needed. The interface provides real-time feedback, diagnostic information, and visualization of the machining operations, enhancing control and productivity.

- Workpiece Clamping and Fixturing: CNC turning machines offer various options for securely clamping and fixturing workpieces. This ensures stability during machining and reduces the risk of workpiece movement or vibrations, leading to precise and accurate results.

- Precision and Accuracy: CNC turning machines are known for their high precision and accuracy. They can achieve tight tolerances and produce smooth surface finishes, meeting the requirements of industries such as automotive, aerospace, medical, and more.

While the specific features of the “Galaxy 440V Midas 10 CNC Turning Machine” may differ, these general features represent the typical capabilities and functionalities of CNC turning machines

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.