HAAS VF E Vertical Machining Center

₹15.00 Lakh

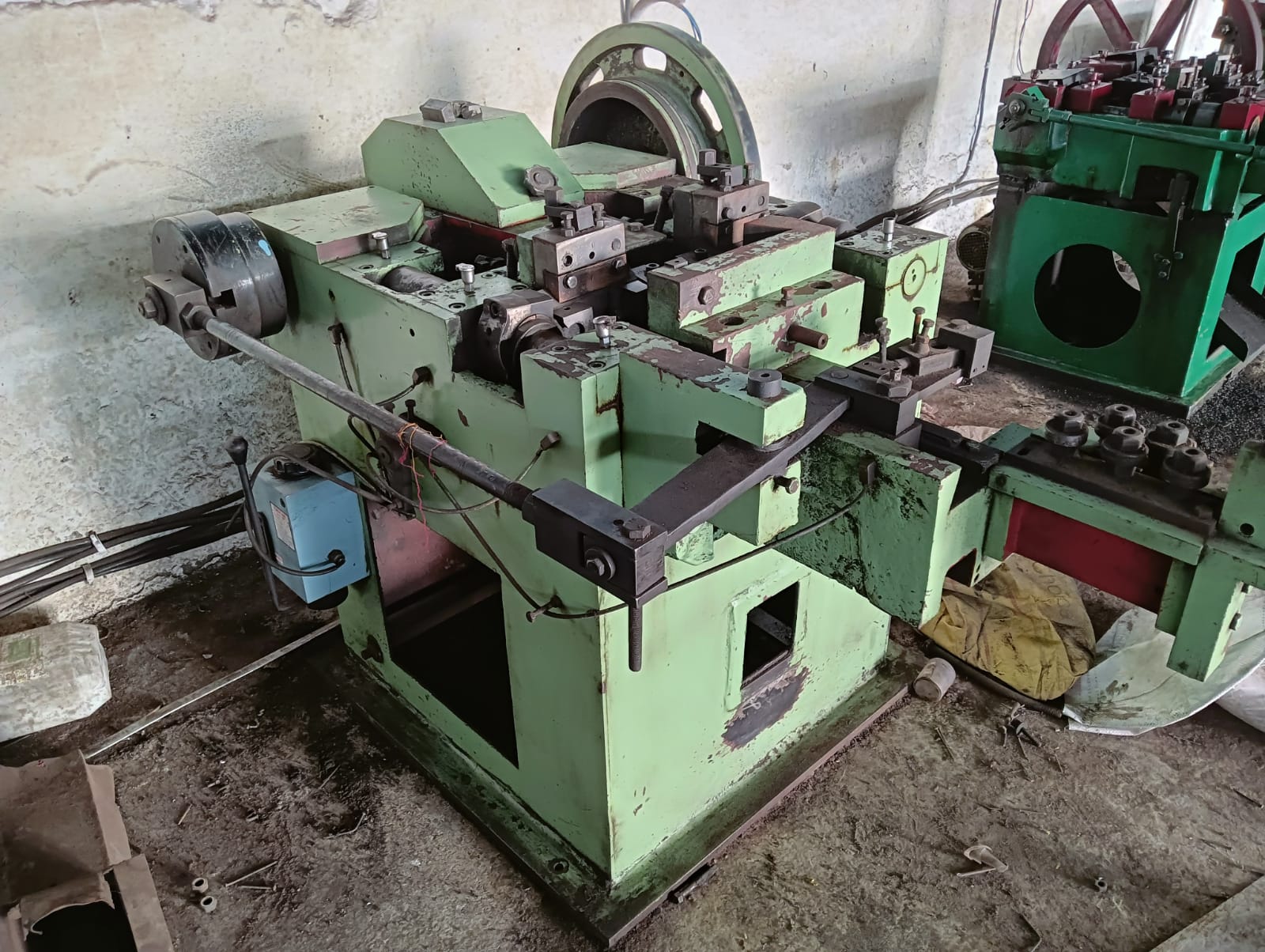

This is a HAAS VF E Vertical Machining Center

Product Specification

| Brand | HAAS |

| Model Number | VF E |

| Table Size | 26 |

| Automation Grade | Automatic |

| Spindle Speed | 0 – 7500 RPM |

| Travels XYZ | 20 X 16 X 20 |

| Condition | Second hand |

| MACHINE CONTROL | HAAS 32 Bit CNC |

| SPINDLE TO TABLE DISTANCE | 4 |

| TABLE CAPACITY | 3000 LBS |

| SPINDLE TAPER | Cat 40 Taper |

| MAX CUTTING FEED RATE | 300 IPM |

| SPINDLE DRIVE | 20 HP Vector Spindle Drive |

The Haas VF E Vertical Machining Center is part of Haas Automation’s popular VF series, which stands for “Vertical Machining Center – Enhanced.” Haas Automation is a leading manufacturer of CNC machine tools, and the VF series is known for its reliability, performance, and versatility. The “E” in the model name typically indicates the machine has enhanced features and capabilities compared to the standard VF series.

Here are some key features and characteristics of the Haas VF E Vertical Machining Center:

- Vertical Machining Center (VMC): The VF E is a vertical machining center, which means the spindle axis is aligned vertically, and the cutting tool moves along the X, Y, and Z axes. This configuration is ideal for a wide range of machining operations and is commonly used for milling, drilling, tapping, and other cutting processes.

- Enhanced Features: The “E” designation signifies that the VF E model may come with enhanced features and functionalities compared to the standard VF series. These enhancements could include improvements in spindle speed, tool capacity, rapid traverse rates, or additional options for increased productivity and performance.

- CNC Control: Like all Haas machines, the VF E is equipped with a Haas CNC control, which is user-friendly and easy to program. The CNC control interprets part programs written in G-codes and M-codes, allowing for precise and automated machining operations.

- High-Quality Construction: Haas machining centers are built to high-quality standards, ensuring stability, rigidity, and accuracy during machining operations. The robust construction allows for heavy-duty cutting and consistent performance.

- Tool Changer: The VF E is likely to have an automatic tool changer (ATC) that can hold multiple cutting tools. The ATC enables quick and automatic tool changes, reducing setup time and increasing productivity.

- Spindle Options: Haas VF E machines may come with various spindle options, offering different speed and power capabilities to accommodate a wide range of machining requirements.

- Versatility: The VF E series is designed to be versatile and flexible, capable of handling various materials and accommodating diverse machining applications.

- Applications: The Haas VF E Vertical Machining Center is suitable for a wide range of industries and applications, including aerospace, automotive, mold making, medical, and general precision machining.

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.

This is a HAAS VF E Vertical Machining Center

Product Specification

| Brand | HAAS |

| Model Number | VF E |

| Table Size | 26 |

| Automation Grade | Automatic |

| Spindle Speed | 0 – 7500 RPM |

| Travels XYZ | 20 X 16 X 20 |

| Condition | Second hand |

| MACHINE CONTROL | HAAS 32 Bit CNC |

| SPINDLE TO TABLE DISTANCE | 4 |

| TABLE CAPACITY | 3000 LBS |

| SPINDLE TAPER | Cat 40 Taper |

| MAX CUTTING FEED RATE | 300 IPM |

| SPINDLE DRIVE | 20 HP Vector Spindle Drive |

The Haas VF E Vertical Machining Center is part of Haas Automation’s popular VF series, which stands for “Vertical Machining Center – Enhanced.” Haas Automation is a leading manufacturer of CNC machine tools, and the VF series is known for its reliability, performance, and versatility. The “E” in the model name typically indicates the machine has enhanced features and capabilities compared to the standard VF series.

Here are some key features and characteristics of the Haas VF E Vertical Machining Center:

- Vertical Machining Center (VMC): The VF E is a vertical machining center, which means the spindle axis is aligned vertically, and the cutting tool moves along the X, Y, and Z axes. This configuration is ideal for a wide range of machining operations and is commonly used for milling, drilling, tapping, and other cutting processes.

- Enhanced Features: The “E” designation signifies that the VF E model may come with enhanced features and functionalities compared to the standard VF series. These enhancements could include improvements in spindle speed, tool capacity, rapid traverse rates, or additional options for increased productivity and performance.

- CNC Control: Like all Haas machines, the VF E is equipped with a Haas CNC control, which is user-friendly and easy to program. The CNC control interprets part programs written in G-codes and M-codes, allowing for precise and automated machining operations.

- High-Quality Construction: Haas machining centers are built to high-quality standards, ensuring stability, rigidity, and accuracy during machining operations. The robust construction allows for heavy-duty cutting and consistent performance.

- Tool Changer: The VF E is likely to have an automatic tool changer (ATC) that can hold multiple cutting tools. The ATC enables quick and automatic tool changes, reducing setup time and increasing productivity.

- Spindle Options: Haas VF E machines may come with various spindle options, offering different speed and power capabilities to accommodate a wide range of machining requirements.

- Versatility: The VF E series is designed to be versatile and flexible, capable of handling various materials and accommodating diverse machining applications.

- Applications: The Haas VF E Vertical Machining Center is suitable for a wide range of industries and applications, including aerospace, automotive, mold making, medical, and general precision machining.

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.