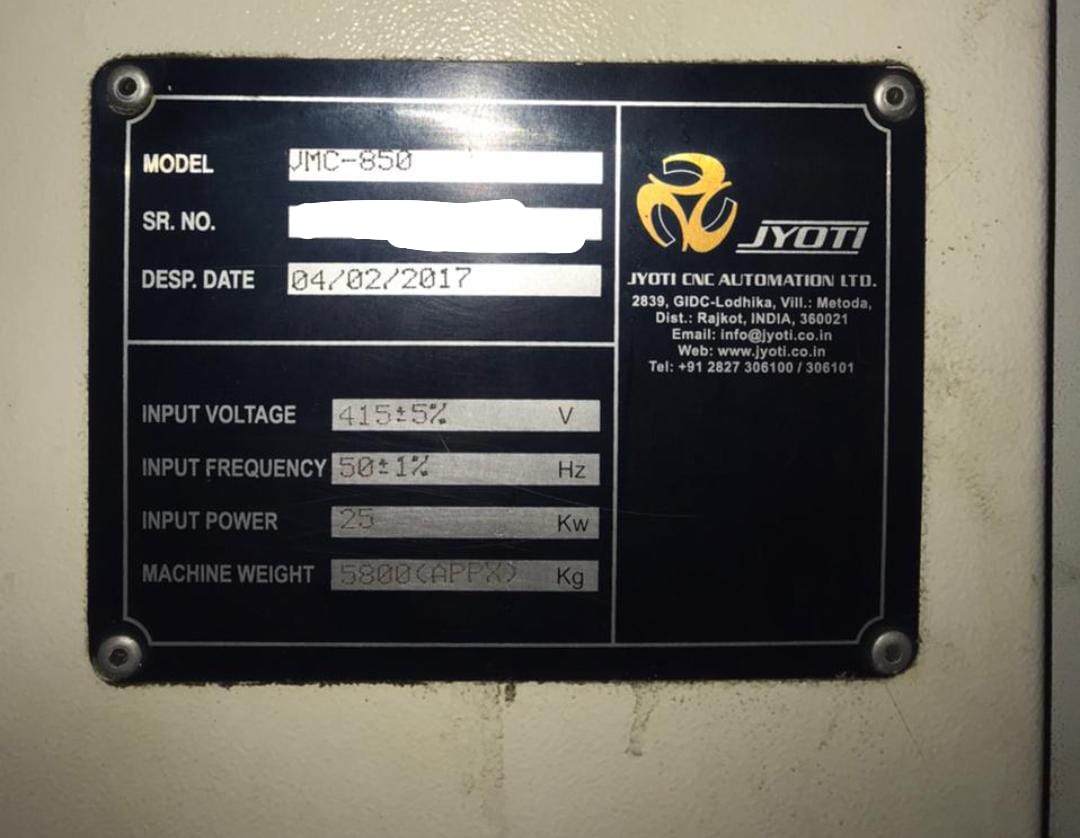

Jyoti Vertical Machining Center VMC 850

₹19.00 Lakh

This is a Jyoti Vertical Machining Center VMC 850

Product Description

| Table: | ||||||||

|

||||||||

| Capacity: | ||||||||

|

||||||||

| Main Spindle: | ||||||||

|

||||||||

| Accuracy (as per VDI/DGQ 3441): | ||||||||

|

||||||||

| Feed: | ||||||||

|

||||||||

| Automatic Tool Changer: | ||||||||

|

||||||||

| Other Data: | ||||||||

|

The Jyoti VMC 850 is a specific model of vertical machining center (VMC) manufactured by Jyoti CNC Automation Ltd., an Indian company specializing in CNC machine tools. The VMC 850 is designed for precise and efficient machining operations, offering a range of features and capabilities. While I don’t have access to the specific details of this model, I can provide you with general information about vertical machining centers and some features commonly found in Jyoti machines.

- CNC Control System: The VMC 850 is equipped with a computer numerical control (CNC) system that allows for precise control over the machining process. The CNC system interprets coded instructions and controls the movement of the cutting tools and workpiece to achieve accurate and consistent results.

- Vertical Spindle: The machine features a vertical spindle that holds the cutting tools and rotates at high speeds to perform various machining operations. The spindle may have variable speed and power capabilities to accommodate different materials and cutting requirements.

- X, Y, Z Axes: The VMC 850 typically has three axes of movement—X, Y, and Z axes. The X-axis represents the horizontal movement of the table, the Y-axis represents the vertical movement of the table, and the Z-axis represents the movement of the spindle in and out of the workpiece. These axes allow for multi-directional machining and precise positioning of the cutting tools.

- Tool Changer: The machine may feature an automatic tool changer (ATC) that allows for the quick and automatic exchange of cutting tools. The tool changer can hold multiple tools, increasing productivity by reducing manual tool changes and setup time.

- Worktable: The VMC 850 is equipped with a worktable where the workpiece is secured during machining. The worktable can have a range of sizes and configurations, depending on the specific model and requirements.

- Control Interface: The machine may feature a user-friendly control interface that allows operators to program and monitor the machining process. The interface can include a touchscreen or a keypad for inputting commands and parameters.

- Accuracy and Precision: Jyoti machines are known for their precision and accuracy. They may incorporate features such as high-quality linear guides, precision ball screws, and advanced servo systems to ensure minimal backlash and precise machining results.

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.

This is a Jyoti Vertical Machining Center VMC 850

Product Description

| Table: | ||||||||

|

||||||||

| Capacity: | ||||||||

|

||||||||

| Main Spindle: | ||||||||

|

||||||||

| Accuracy (as per VDI/DGQ 3441): | ||||||||

|

||||||||

| Feed: | ||||||||

|

||||||||

| Automatic Tool Changer: | ||||||||

|

||||||||

| Other Data: | ||||||||

|

The Jyoti VMC 850 is a specific model of vertical machining center (VMC) manufactured by Jyoti CNC Automation Ltd., an Indian company specializing in CNC machine tools. The VMC 850 is designed for precise and efficient machining operations, offering a range of features and capabilities. While I don’t have access to the specific details of this model, I can provide you with general information about vertical machining centers and some features commonly found in Jyoti machines.

- CNC Control System: The VMC 850 is equipped with a computer numerical control (CNC) system that allows for precise control over the machining process. The CNC system interprets coded instructions and controls the movement of the cutting tools and workpiece to achieve accurate and consistent results.

- Vertical Spindle: The machine features a vertical spindle that holds the cutting tools and rotates at high speeds to perform various machining operations. The spindle may have variable speed and power capabilities to accommodate different materials and cutting requirements.

- X, Y, Z Axes: The VMC 850 typically has three axes of movement—X, Y, and Z axes. The X-axis represents the horizontal movement of the table, the Y-axis represents the vertical movement of the table, and the Z-axis represents the movement of the spindle in and out of the workpiece. These axes allow for multi-directional machining and precise positioning of the cutting tools.

- Tool Changer: The machine may feature an automatic tool changer (ATC) that allows for the quick and automatic exchange of cutting tools. The tool changer can hold multiple tools, increasing productivity by reducing manual tool changes and setup time.

- Worktable: The VMC 850 is equipped with a worktable where the workpiece is secured during machining. The worktable can have a range of sizes and configurations, depending on the specific model and requirements.

- Control Interface: The machine may feature a user-friendly control interface that allows operators to program and monitor the machining process. The interface can include a touchscreen or a keypad for inputting commands and parameters.

- Accuracy and Precision: Jyoti machines are known for their precision and accuracy. They may incorporate features such as high-quality linear guides, precision ball screws, and advanced servo systems to ensure minimal backlash and precise machining results.

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.