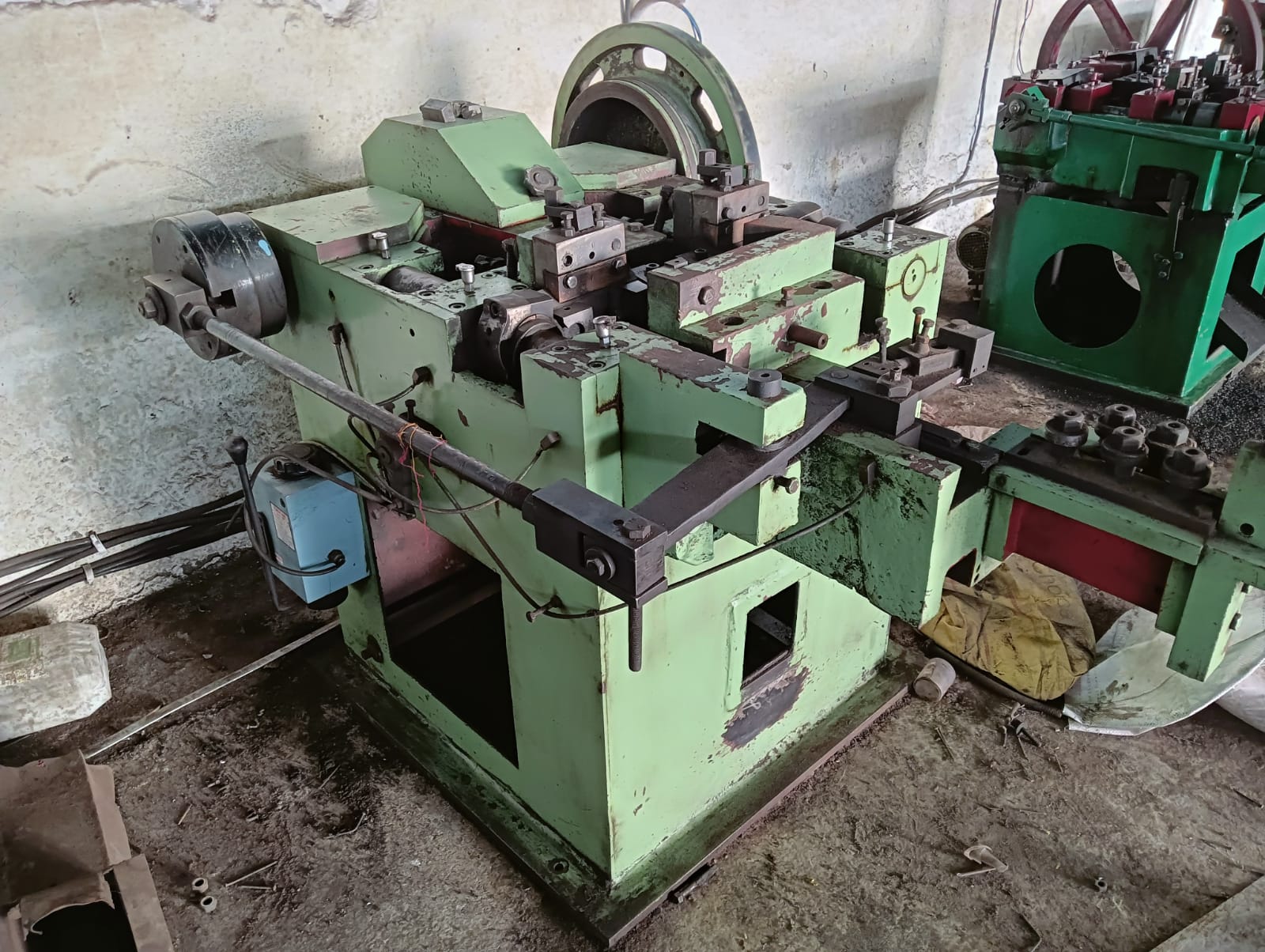

This is a N3 Automatic Nail Making Machine

Machine Production Capacity : upto 400kg/hr

Machine Finish Product Range: 1.5inch-3inch length and 12gauge to 9gauge thickness

Product Specification

| Automation Grade | Automatic |

| Phase | Three Phase |

| Motor Power | 3 HP |

| Length of Nail | 1″-“ |

| Approx Gross Weight | 850 kg |

| Production Per Minute | 3000Piece |

| Material | MS |

The N3 Wire Nail Making Machine is a specific model of wire nail making machine used for the production of nails from wire coils. While I don’t have access to the specific details of this model, I can provide you with general information about wire nail making machines and their typical features.

- Wire Feeding and Straightening: The machine is equipped with a wire feeding mechanism that straightens and guides the wire from a coil into the nail making process. This ensures a continuous feed of wire for nail production.

- Nail Forming: The machine consists of a series of dies and punches that shape the wire into nails. The wire is cut, formed, and headed to create the desired nail shape and size. The exact configuration of the dies and punches may vary depending on the specific machine model.

- Speed and Production Capacity: The machine’s speed and production capacity depend on the specific model and its capabilities. Higher-end models often offer faster production speeds and higher nail output per minute.

- Nail Size and Variety: Wire nail making machines can typically produce a range of nail sizes, from small nails used for carpentry and construction to larger nails for industrial applications. The machine may have adjustable settings to accommodate different nail sizes and types.

- Control System: The machine may feature a control system that allows for easy operation and adjustment of various parameters, such as nail length, thickness, and production speed.

- Wire Coil Feeding and Collection: The machine may have mechanisms to feed wire coils into the machine and collect the finished nails. This ensures a continuous supply of wire and efficient collection of the produced nails.

- Safety Features: Wire nail making machines often incorporate safety features such as protective guards, emergency stops, and safety sensors to ensure the safety of operators during operation.

High speed and low maintenance cost.

Single phase machine in a good working condition and no pending loan.

It has been recently serviced.