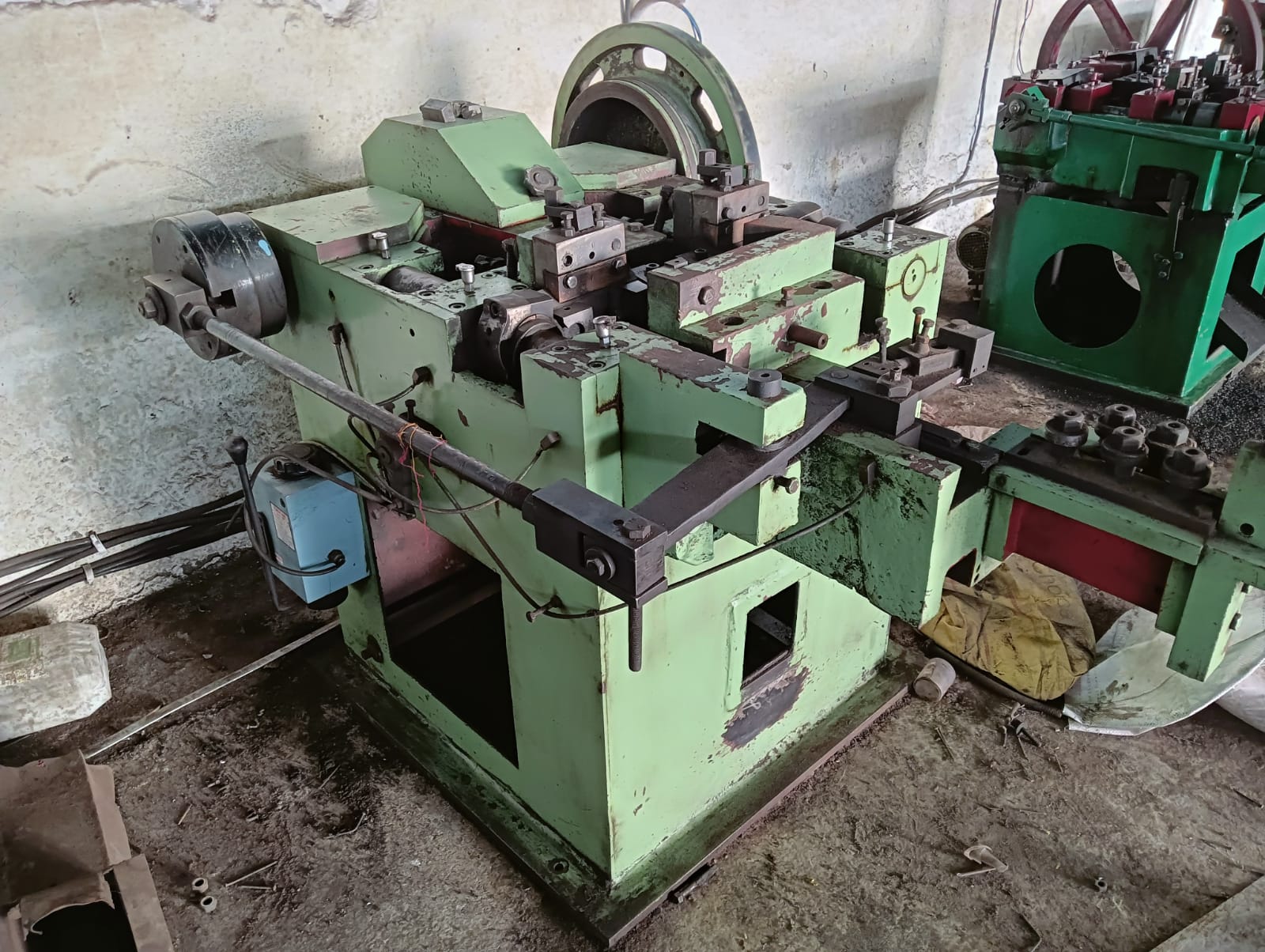

This is SMBI Paper Bag Making Machine

Product Specification

| Type Of Bag | Grain Bag |

| Bag Material | paper |

| Capacity | 80-100 (Pieces per hour) |

| Max Bag Length | 1-100 mm, 100-200 mm, 200-300 mm, 300-400 mm, 400-500 mm |

| Model | 3 |

| Power | SINGLE PHASE |

| Brand | SMBI |

| Size | 32 |

| Automation Grade | Automatic |

| Max Bag Width | 400-500 mm |

An automatic paper bag making machine is a mechanical device designed to produce paper bags in an automated fashion. These machines are commonly used in industries such as packaging, retail, and food services to manufacture a large volume of paper bags efficiently and consistently. Here are some key components and features of a typical automatic paper bag making machine:

- Paper Feeding System: The machine is equipped with a paper feeding system that takes in a roll of paper and feeds it into the machine for bag production. The paper can be in the form of a roll or sheet, depending on the machine design.

- Printing Unit (optional): Some machines may have an integrated printing unit that allows for custom designs, logos, or text to be printed on the paper before bag formation. This feature enables branding and customization options.

- Bag Forming Section: The bag forming section is responsible for shaping and sealing the paper into a bag. It typically consists of rollers, folding mechanisms, and adhesive application systems. The machine can create various bag styles such as flat-bottom bags, gusseted bags, or square-bottom bags.

- Handle Attachment (optional): If the paper bags require handles, an automatic handle attachment unit may be included. This unit can attach handles made of paper, rope, or other materials to the bags during the bag forming process.

- Cutting and Gluing System: The machine incorporates a cutting mechanism to separate the paper into individual bags. It can also have a gluing system that applies adhesive to seal the edges or flaps of the bags.

- Control Panel: An automatic paper bag making machine typically includes a control panel that allows the operator to set various parameters such as bag size, speed, and other production settings. It provides monitoring and control over the machine’s operation.

- Conveyor System: A conveyor system may be integrated to transport the finished paper bags from the machine to a collection area or downstream processes. It ensures a smooth flow of bags and facilitates automation in the production line

It is in a good working condition

It has been recently serviced.

No pending loan against the machine.